Forging Explained

The metal forging market is divided into open-die, closed-die, and ring forging. In 2022, the open die segment dominated the metal forging market in revenue. Open die forging is suitable for forming simple components, such as sleeves, flats, rounds, hexes, discs, shafts, hubs, blocks, cylinders, and other custom shapes. Since it uses an open die, the workpiece’s size and weight are not a limiting factor. The other process, closed die forging, is extensively used for small components, as the size of the job piece is limited to the size of the dies. On the other hand, ring forging is expected to grow with a higher CAGR during the forecast period. Typically, the parts and components made using ring forging are machines, robotics, valves, bearings, clutches, couplings, drives, flanges, gears, and glass-lined reactors.

The Forging Industry Forecast

The North American forging industry market is over 14 billion USD, while Mexico’s share is less than $800 Million. Based on the automotive industry’s reports, Mexico’s capabilities are less than OEMs expect to meet their nearshoring challenges. One of the tailwinds facing the industry is the growth in Electric Vehicle production. Internal combustion engines require over 2000 forged parts, while electric vehicles require less than 100.

Much of the $800 Million of forgings produced in Mexico is by large global automotive and aerospace manufacturers such as American Axle, Coulter Forge, Precision Castparts, and Japanese suppliers such as Aichi Forge. There is a large demand for custom forgings in different sizes and materials.

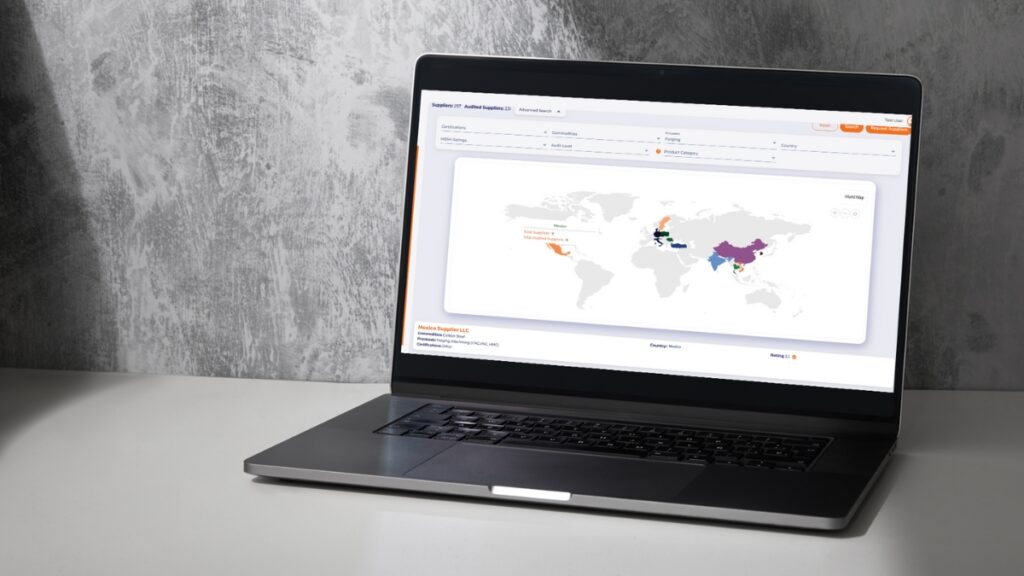

The Impact of MESH Global Sourcing

The MESH Sourcing Platform includes nine forging suppliers in Mexico. All have Carbon Steel material capabilities and a large share of forgings. Four even have Aluminum forging capabilities, which are specialized for demanding applications such as Automotive Yokes.

S3146 features three facilities in Mexico, employs 500 people, carries IATF and ISO14001 certifications, and processes various materials and applications.

S1114 features a division of a German precision forging company. Based in Queretaro, with 430 employees, it has a large open capacity due to the aforementioned changes to Electric Vehicles. With a rating of 4.69 Level 1 audit, this supplier is well-positioned to develop the most demanding aerospace and automotive forging applications.

The forging industry is growing in aerospace applications, and the fastest-growing materials are Titanium and Magnesium. S1133, with a facility in the industrial hub of Nuevo Leon, has magnesium capabilities fit for various needs.

How MESH Can Improve Your Sourcing Strategy

MESH Sourcing includes 257 forging suppliers in over 14 countries. Contact MESH to help you find suppliers and achieve your near-shoring and global supply chain resilience goals!

https://www.trade.gov/market-intelligence/mexico-metal-mechanics

https://www.statista.com/statistics/727327/metal-forgings-stampings-production-value-mexico/