What is a sourcing audit?

Sourcing in today’s complex marketplace can be overwhelming for any buyer. The challenge lies in identifying reliable suppliers, evaluating their capabilities, and building trustworthy relationships. In response to these hurdles, sourcing audits for procurement are crucial to streamline procurement and ensure the highest quality standards. This article explores the benefits of the MESH Sourcing Audit, its superiority over traditional procurement directories, and why it is indispensable for successful and stress-free sourcing experiences.

Sourcing audits for procurement hold the key to credibility in supplier selection. Conducted by highly experienced quality auditors or sourcing engineers, these evaluations provide buyers with firsthand insights into a supplier’s effectiveness, controls, and processes. The auditors’ expertise enables them to assess the supplier’s capabilities accurately. MESH sourcing audits build confidence in procurement by ensuring buyers can access genuine and verified information.

Why use a MESH Sourcing Audit?

The logic behind the MESH Sourcing Audit is clear-cut and compelling. Some may exaggerate their capabilities in a marketplace teeming with suppliers seeking attention. Procurement directories relying solely on supplier-provided information can fall prey to this predicament. However, our sourcing audits for procurement cut through the noise and deliver objective evaluations based on on-site observations. This method eliminates the risk of unforeseen issues, ultimately saving buyers from costly delays and unwanted surprises.

The necessity of sourcing audits is significant. The prospect of investing resources into a partnership with a misrepresented supplier can evoke stress and anxiety. These emotions can be particularly detrimental to quality, sourcing, and sales organizations where the stakes are high. Opting for the MESH Sourcing Audit provides peace of mind as buyers make informed decisions, fostering clarity and promoting mutual satisfaction in manufacturing.

What is in the MESH Audit?

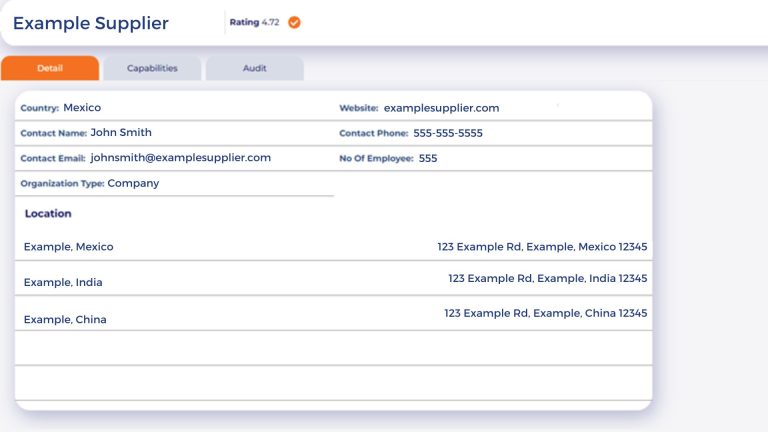

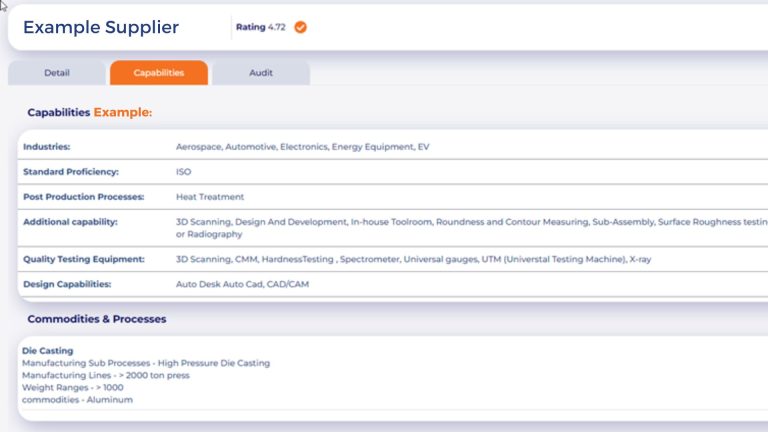

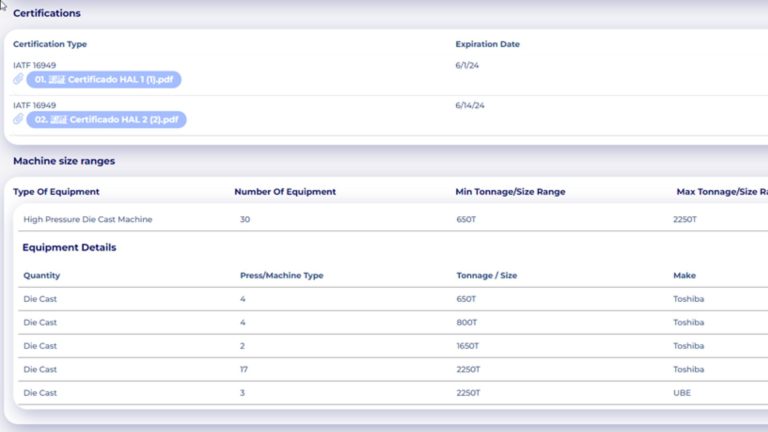

Below is an example of what you can see in the MESH Portal when viewing a supplier profile. You can see details of the supplier’s portfolio, capabilities, and information on the MESH Sourcing audit.

The MESH Sourcing Audit is a seven-section assessment that includes various aspects of a quality systems audit. Check out the questions in each section and the required imagery.

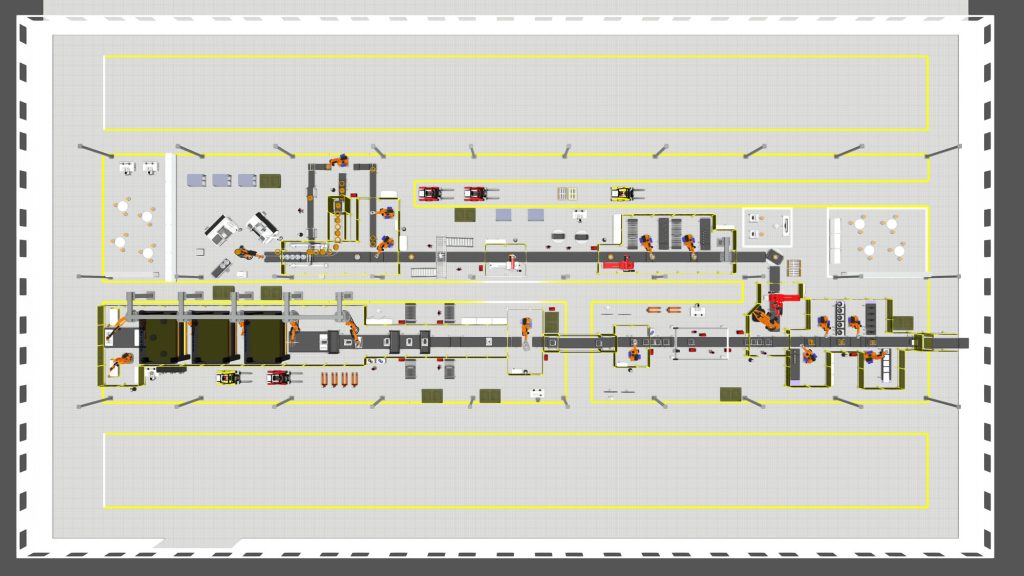

Manufacturing – Plant, Equipment, Layout and Processes (Observations/Comments from Factory Tour)

- Was the manufacturing activity at a high, medium, or low level at the time of the plant tour?

- Does the product flow well from process to process?

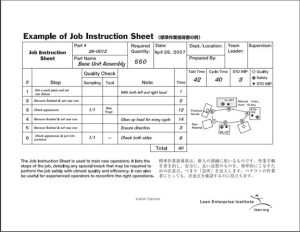

- Are work instructions and inspection instructions visible at every workstation? Are the instructions consistent with the products being built during the assessment?

- Do work instructions include photographs and graphics in addition to verbal descriptions?

Manufacturing – Support Processes

- Does the company support lot traceability while maintaining lot testing data?

- At what general percentage of capacity utilization is the plant operating currently?

- If custom tooling is required, (e.g. plastic injection molding) does the company manufacture the tooling in-house?

- What is the company’s primary production planning tool?

- What is the company’s on-time delivery performance over the past two years?

- When was the last surveillance audit?

- Does the company have a formal corrective action process to solve manufacturing, technical, or quality problems?

- Does the company have a formal material receipt inspection process for measuring/testing incoming material to technical requirements? Are regular records of this inspection process kept?

- List the major pieces of testing and measuring equipment.

- Please rate the company’s formal calibration program for testing instructions and calibration devices.

- How well does the company segregate non-conforming material (NCM)? Note how it is done in the production, inspection, and storage areas.

- Please rate the company’s formal APQP or project management procedure for starting new projects in the plant.

- Is the supplier prepared and able to provide whatever production samples and pre-production test reports the customer requires?

- Describe the engineering team’s English skills (primarily written ability).

- List the design tools the company uses. Highlight the tool the company uses most frequently (i.e., CAD, CAM).

- What is the typical lead time of the company’s product? (Lead time is the time between receiving a customer order and shipping the same order).

- Please rate the company’s export experience and support. In the comment section, please list the customers to whom the company exports its primary production.

- Please rate the suppliers’ packaging experience, particularly in export packaging.

- One or more videos of the inside of the plant.

- One or more videos displaying the outside of the factory.

Why is it essential to use the MESH Sourcing Audit?

After a MESH Audit, suppliers are given a MESH Rating on a scale of 1-5 to determine their ability to meet the audit’s standards. Ratings are listed next to the suppliers’ names in the MESH portal so buyers can quickly identify the supplier’s quality. Buyers can also review the procurement sourcing audits to see what aspects the suppliers fulfilled and determine if they are compatible as business partners.

While other procurement directories may offer supplier information, the absence of the MESH Sourcing Audit is a significant drawback. Buyers risk partnering with suppliers who overstate their abilities without these comprehensive evaluations, leading to unsatisfactory results. Sourcing audits for procurement distinguish themselves by providing reliable, transparent, and unbiased assessments of suppliers’ strengths and weaknesses. This contrast highlights the superiority of sourcing audits regarding supplier evaluation.

The MESH Sourcing Audit is invaluable for buyers seeking to procure from reputable suppliers. Embracing the MESH Sourcing Audit empowers buyers to make informed decisions and forge trustworthy partnerships with suppliers. As buyers navigate the global marketplace, the choice becomes clear – embrace the power of sourcing audits for procurement and unlock the true potential of procurement. By avoiding pitfalls such as inaccurate supplier information and unexpected setbacks, the MESH Sourcing Audit promotes successful and stress-free sourcing experiences.

Find top-rated suppliers for your manufacturing needs here.

Want to explore MESH in detail? Book Demo Now.