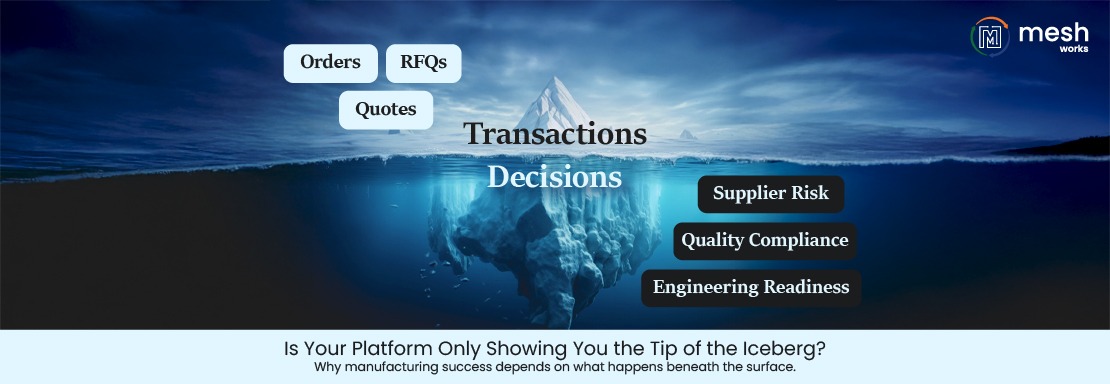

Over the past decade, manufacturing platforms have changed quickly. They started as systems to digitize transactions like RFQs, quotes, orders, and documents. Now, become a crowded ecosystem of tools promising speed and efficiency.

Still, many procurement, sourcing, and engineering teams still struggle with the same core problems: slow decisions, teams not working together, and unexpected issues late in the process.

The issue is not a lack of platforms.

The real problem is that most platforms are designed to handle transactions, not to help people make better decisions.

The Problem with Transactional Systems in Manufacturing

Transactional platforms are designed to answer questions like:

Was the RFQ sent?

Was the quote received?

Was the order placed?

Was the document uploaded?

These systems do a good job of tracking activity. However, they often fail to help teams answer the questions that really matter:

Which supplier is the right fit, not just the lowest cost?

What risks exist before we award the business?

Are suppliers truly ready from an engineering and quality standpoint?

What commitments were made, and are they being met?

When platforms focus only on transactions, decision-making stays manual, subjective, and fragmented.

Why Decisions Are Still Made Outside the Platform

In many organizations, the most important sourcing and supplier decisions are still made in a few familiar ways:

Using spreadsheets

Over email threads

In offline meetings

Rely on individual judgment instead of shared visibility

This leads to three main problems:

1. Fragmented Context

Procurement, engineering, and quality teams often use different data sets. There isn’t one system that gives a full view of supplier capability, readiness, risk, and commitments.

2. Inconsistent Decision Criteria

When there is no structured evaluation or shared visibility, different stakeholders assess suppliers in different ways. This causes rework, delays, and internal friction.

3. Late Risk Discovery

If platforms only track transactions, risks often show up after the award, such as during APQP, production, or delivery. At that point, fixing problems is costly and disruptive.

Manufacturing risk comes from the decisions we make

In manufacturing, risk usually doesn’t come from just one transaction. It builds up through a series of decisions:

Who is shortlisted

How suppliers are evaluated

What trade-offs are accepted

What assumptions go unchallenged

Platforms that only track transactions show what happened after decisions are made, not during the decision process.

This difference is important.

What Decision-Support Platforms Do Differently

Platforms designed to support decisions help teams:

They make it easier to compare suppliers using the same standards every time

Connect sourcing data with engineering and quality checks

Track of commitments even after contracts are awarded

Bring stakeholders together before making final decisions

Reduce reliance on individual judgment

Rather than just asking, “Did this happen?”, these platforms help teams consider:

“Is this the right decision?”

This change turns these platforms from simple tools into valuable strategic resources.

The Cost of Staying Transaction-Focused

If manufacturing platforms focus only on transactions, organizations often face the following problems:

Sourcing cycles slow down, even when digital tools are in place.

Supplier problems keep happening in different programs.

There are weak transitions between sourcing, engineering, and quality teams.

It becomes hard to explain or repeat decisions.

In today’s unpredictable global market, where supply chains deal with policy changes, cost pressures, and limited capacity, these problems can get worse very quickly.

Where Manufacturing Platforms Are Headed

Leading manufacturers are shifting to platforms that:

Bring together sourcing, supplier evaluation, quality, and execution

Give a clear view of the entire supplier lifecycle

Help teams make decisions faster and with more confidence

Lower risks later by making things clearer earlier in the process

This isn’t just about adding more features.

It’s about changing what platforms do, moving from simply keeping records to actually helping people make decisions.

What This Means for MESH Works

MESH Works is built to support this change.

Instead of just handling transactions, the platform helps buyers, suppliers, and engineering teams make better decisions throughout sourcing, evaluation, and execution. By combining structure, visibility, and accountability in one place, MESH Works helps teams reduce risk before it becomes a problem.

The goal is not only to move faster, but also to move forward with confidence.

Final Thought

Transactions show what has already happened.

Decisions shape what comes next.

In manufacturing, platforms that help with decisions, not just transactions, are the ones that build long-term value.

Curious about how decision-driven manufacturing platforms work in real situations?

MESH Works helps procurement, engineering, and quality teams go beyond transactions by offering structured workflows, shared visibility, and accountability throughout the sourcing process.

Book a demo or reach out to us to see how MESH Works can help you make better sourcing and supplier decisions.